High Gloss Panel Finishing Line

AVAILABLE ITEMS

This finishing line is widely used in high-gloss coating process of flat plates such as wardrobes, kitchen cabinets, wall cabinets, bathroom cabinets, sliding doors, 3D printing video wall, ceramic tile wall, ceramic inkjet printing panels, etc.

WORKING THEORY

The curtaining film layer is formed by the pressure of a diaphragm pump, the coating thickness is easy to adjust, and the coating layer distribution is uniform.

The transporting speed of the curtain coater can be set up to 80m/min, which makes the UV lacquer distributing on the surface of the panel uniformly and reduces the thickness of the coating layer.

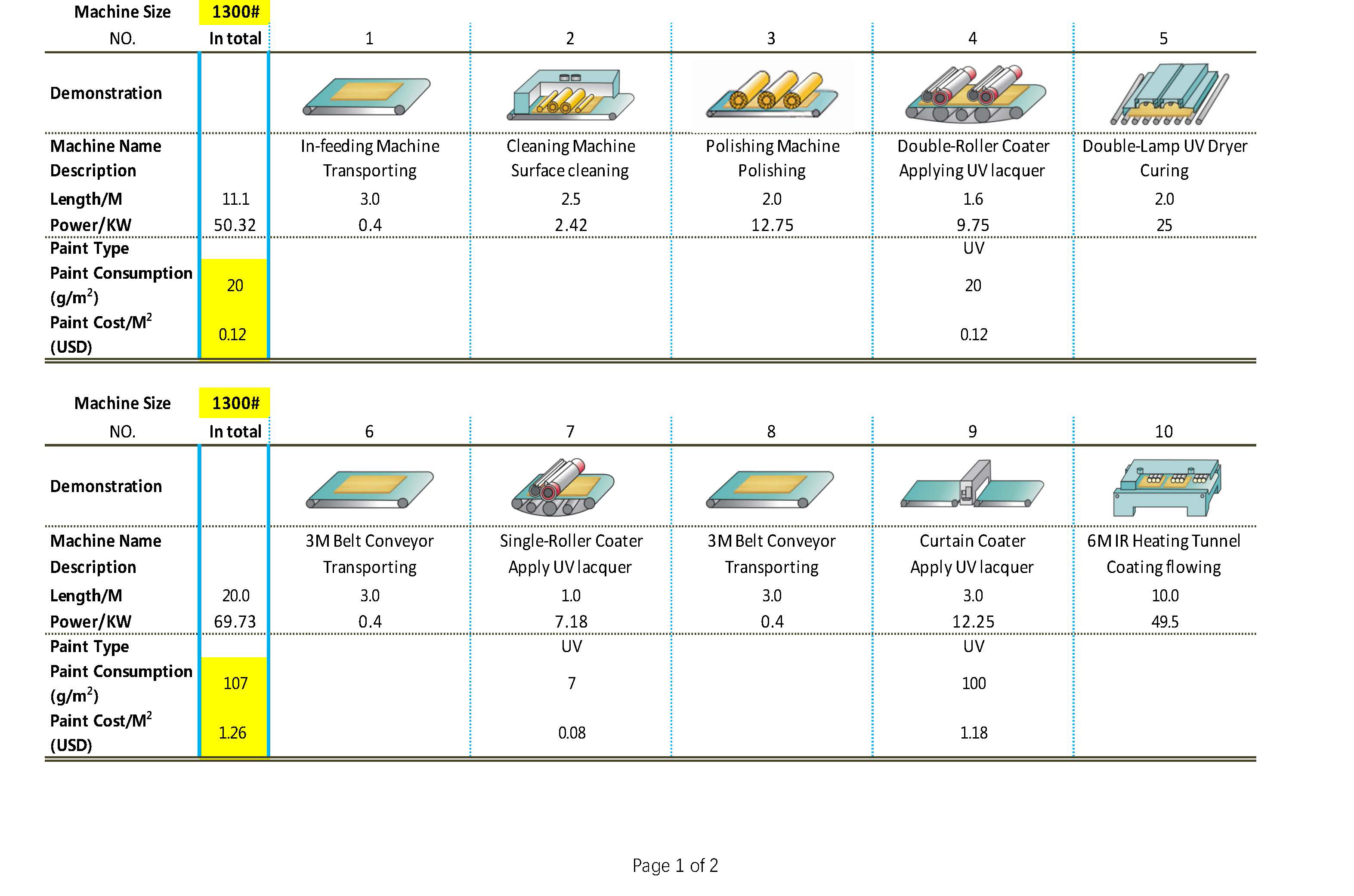

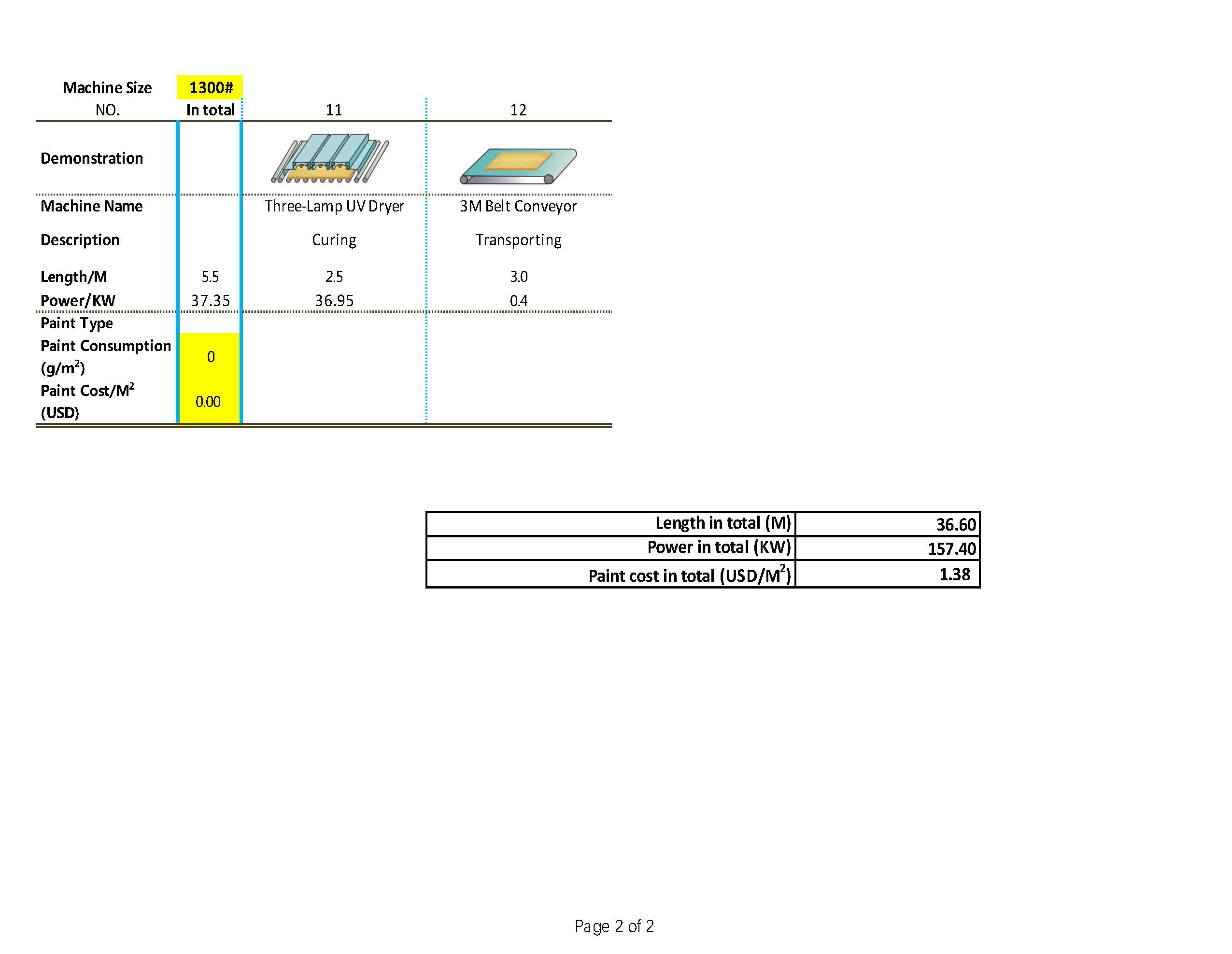

STANDARD FINISHING PROCESS

ADVANTAGES

The UV curtain coating finishing line has an average daily production capacity of more than 2,000 sheets, and the coating film can be adjusted to 0.06mm.

The coating layer thickness can be very precise, which ensures the uniformity of the panel surface.

This finishing line is easy to operate and clean.

In conjunction with the paint circulation system, this is an environmentally-friendly coating production line with high output, high efficiency and high return.

For more information, please contact us through sales@ljmachine.com